We produce custom windows, hatches and portholes for marine, commercial and industrial applications. We propose solutions for specific, made-to-measure window replacements, as well as for the requirements of major boat builders.

Our windows can be fixed, sliding, porthole or hinged. They are easily installed and require no screws or holes drilled through your hull.

Please see the photo gallery to inspect a few boats which have our windows installed.

Our window frames are produced from 6063 marine grade aluminum for wall thickness ranging from 0.125" up to 2.5". Bent for following opening radii of 2", 3" and 4", for hinged windows R=3". Windows are produced with clear, or optionally black, anodized finish.

See our Window installation manual

Powder Coating

Powder coating can be supplied in a variety of colors. However, please note that there is no warranty on powder coated frames for failure of the powder coat.

Screens

Screens can be provided for hinged and sliding windows and are produced for the specific window in which they are installed.

Glass color and opacity

| Tempered glass | |||

|---|---|---|---|

| Thickness | Tint color | Light transmittance | |

| 1/4" | Clear | 88% | |

| Green | 75% | ||

| Bronze | 55% | ||

| Grey | 44% | ||

| Graylite #14 | 8% | ||

| 3/8" | Clear | 86% | |

| Green | 66% | ||

| Bronze | 39% | ||

| Grey | 28% | ||

Fixed Windows

Bomon fixed windows are found on the hardest working boats, in trawlers, fire boats as well as in sailboats, marine coast guard vessels, etc.

All our windows, like the ones below, are custom made to suit your application.

Fixed windows are ideal for exposed areas. Bomon fixed windows are waterproof and meet or exceed ABYC and ISO 12216 specifications. The fixed plate, 1/4" (6 mm) or 3/8" (10 mm) thick tempered glass, is compression mounted in our proprietary EPDM-rubber U channel.

of assembly

Sliding Windows

Here’s one of our sliding windows installed in a Back Cove 37', custom made to compliment the traditional elegance of the Back Cove design.

The fixed panel, 0.25" (6 mm) thick tempered glass, is compression mounted in a rubber U channel. The sliding panel, 0.25" (6 mm) thick tempered glass is mounted in PVC wiper track for improved sliding and drainage, vertical and upper tracks have HD weather seal. Vertical rubber seal(s) are installed at mullion to prevent water ingress from weather coming from stern.

Sliding windows are weatherproof, NOT waterproof. If used in adverse conditions, window layout will effect water ingress. Consult us regarding design to reduce/eliminate possible water ingress.

Sliding windows can be produced as horizontal sliders, half drops (sliding plate opens from top down) or guillotine type (sliding plate opens from bottom up). Removable screens are also available as an option.

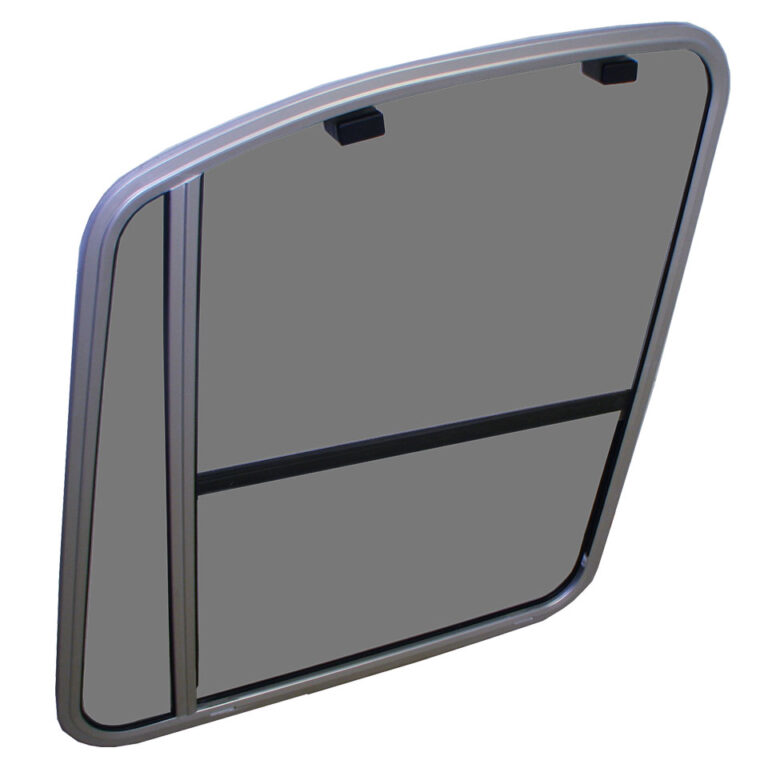

Halfdrop Sliding Windows

Guillotine Sliding Windows

Hinged Windows

The perfect “clamp type” custom-window for exposed areas where improved visibility and ventilation are required.

This window:

- is waterproof

- can be hinged from either the upper horizontal or vertical side profile

- can be produced with plate thicknesses of 1/4" (6 mm) to 5/16" (8 mm). Plate of 3/8" (10 mm) is optional

Hatches

Hatches are identical in construction to the Nova hinged window, but can be built to your specifications using different plate materials such as polycarbonate, acrylic or 1/4" anti-skid aluminum. Nova hatches have drainage slots that allow the hatch to be opened without water ingress.

Frame & Trim

Clamp Type, built from Marine Grade 6063 aluminum post-anodized corners bent on 3" degree radius.

Plate

Glass tempered 0.25" (6 mm) to 5/16" (8 mm) Acrylic or polycarbonate 0.25" to 1/2" Aluminum 1/4" to 3/8".

Hinges

Nova HD proprietary, SS shaft, Teflon® bearings.

Closures

Nylon reinforced plastic, lockable from the inside with two positions — closed and vent (approximate gap of 1/2").

Rubbermount Windows

Flangemount Windows

Flangemount can also be produced as a fixed window.

Air intakes

Frames are produced from 6063 marine grade aluminum and can be bent on 2" or 3" opening radius or made with mitered corners, and can be finished clear or black anodized.

Louver blades are installed in a frame on stacked 0.75" square tube sections which can be spaced between 3/4" and 1.25" apart. This construction eliminates blade vibration and decreases air flow restriction and pressure loss. Angle of louver blades is 35 degrees from horizontal but can be adjusted according to customers preference.

Louver blades are installed in a frame on stacked 0.75" square tube sections which can be spaced between 3/4" and 1.25" apart. This construction eliminates blade vibration and decreases air flow restriction and pressure loss. Angle of louver blades is 35 degrees from horizontal but can be adjusted according to customers preference.

Frame depth can be reduced whilst maintaining structural integrity, to increase flow in upper and lower sections of air intakes. This is of particular interest when overall height or void behind air intakes is limited. Demister pads can be installed capable of eliminating 98% of all salt/water particles up to 200 microns, whilst maintaining air flow at approximately 97% of original volume.

If accessible from the inside, air intakes can be installed with a clamp system similar to the one we use in our windows. If not, they can be fastened from the outside.